1. Definition and Function

VOC concentrators, or volatile organic compound concentrators, are specialized equipment designed for the efficient management and treatment of organic exhaust gases. The primary function of these systems is to concentrate large volumes of low-concentration VOCs into smaller volumes of high-concentration VOCs for subsequent treatment. This process significantly enhances the efficiency and effectiveness of exhaust gas treatment.

2. Applicable Environment

VOC concentrators are particularly suitable for industrial environments where the concentration of VOCs in exhaust gases is relatively low but the volume is large. For instance, industries such as automobile manufacturing, petrochemicals, pharmaceuticals, electronics, machinery, printing, and furniture manufacturing produce large volumes of exhaust gases with low VOC concentrations, making traditional treatment methods less effective. VOC concentrators effectively address this issue, ensuring efficient and economical exhaust gas treatment.

3. Treatment Methods

The concentrated exhaust gases can be treated using various methods, including catalytic oxidation, thermal oxidation, or adsorption. These methods can more effectively remove harmful substances from the exhaust gases, ensuring that the treated exhaust gases meet environmental regulations and improve air quality. VOC concentrators play a crucial bridging role in this process, making exhaust gas treatment more scientific and reasonable.

Advantages of Lv quan Environmental Protection Engineering Technology Co., Ltd. VOC Concentrators

1. Efficient and Universal

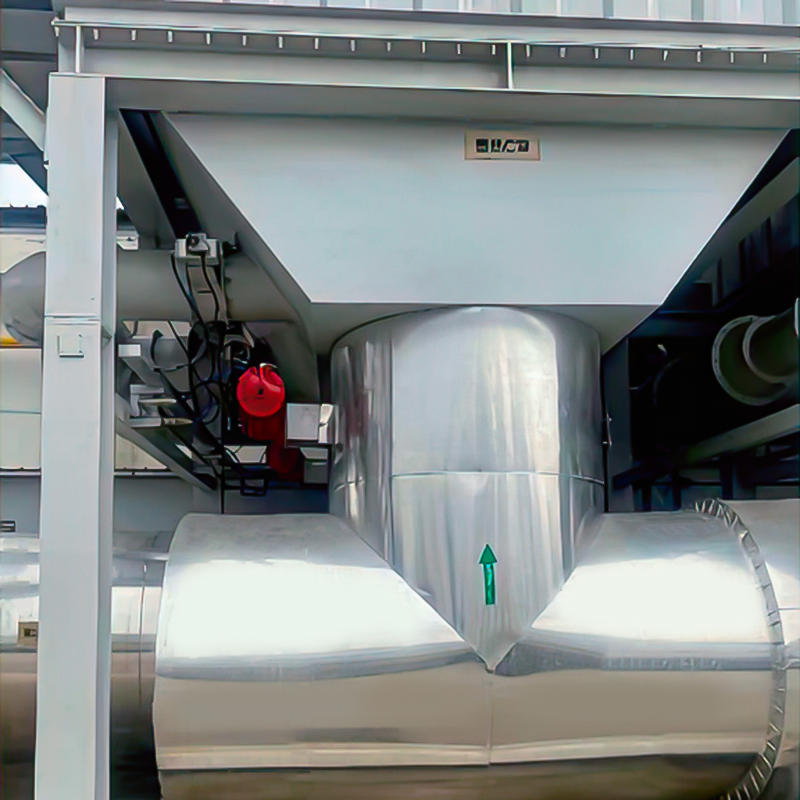

Diverse Product Line: Lv quan Environmental Protection Engineering Technology Co., Ltd. offers multiple types of VOC concentrators, including the LQ-ADW-TO zeolite rotary drum concentrator (tonnage/disk type) + thermal oxidizer (TO), and the LQ-ADW-CO zeolite rotary drum concentrator (disk type) + catalytic oxidation (CO). These systems can handle organic exhaust gases of different concentrations and volumes, ensuring efficient treatment in various industrial applications.

Wide Applicability: The company's VOC concentrators are suitable for multiple industries such as automobile manufacturing, petrochemicals, pharmaceuticals, electronics, machinery, printing, and furniture manufacturing, meeting the diverse needs of different industries.

High Treatment Efficiency: Through advanced concentration technology and optimized design, the VOC concentrators provided by Lv quan Environmental Protection Engineering Technology Co., Ltd. can achieve high-efficiency exhaust gas treatment, ensuring the best treatment results.

2. Advanced Technology Integration

Adsorption Technology: The VOC concentrators from Lv quan Environmental Protection Engineering Technology Co., Ltd. integrate adsorption technology. For example, the LQ-ADW-TO zeolite rotary drum concentrator (cylinder type/disk type) + thermal oxidizer (TO) combines the high adsorption capacity of zeolite to effectively adsorb VOCs in exhaust gases.

Catalytic Oxidation Technology: The company also adopts catalytic oxidation technology, such as the LQ-CFT-CO honeycomb activated carbon adsorption + catalytic oxidation (CO), utilizing the role of catalysts to efficiently remove harmful substances from exhaust gases.

Thermal Oxidation Technology: Through thermal oxidation technology, such as the LQ-ADW-CO zeolite rotary drum concentrator (disk type) + catalytic oxidation (CO), VOCs in exhaust gases are oxidized and decomposed at high temperatures, achieving thorough exhaust gas treatment.

3. Customized Solutions

Personalized Design: Lv quan Environmental Protection Engineering Technology Co., Ltd. provides customized solutions, designing according to the specific needs and exhaust gas characteristics of customers to ensure optimal performance.

Flexible Configuration: The company's VOC concentrators can be flexibly configured according to different types of organic exhaust gases, meeting the needs of various industrial applications.

Strict Standards: Customized solutions strictly adhere to environmental standards and industry norms, ensuring that the treated exhaust gases meet or exceed specified emission standards.

4. Robust and Durable

High-Quality Materials: The VOC concentrators from Lv quan Environmental Protection Engineering Technology Co., Ltd. are manufactured using high-quality materials to ensure long-term durability and reliability.

Thoughtful Design: The equipment is meticulously designed to withstand harsh industrial environments, maintaining stable performance over the long term, reducing maintenance needs and downtime.

Long-Term Stability: The robust design ensures that VOC concentrators can maintain high efficiency and stability during prolonged operation, providing continuous exhaust gas treatment services to customers.

Environmental Compliance and Sustainability

1. High-Level Removal Efficiency

Strict Standards: The VOC concentrators from Lv quan Environmental Protection Engineering Technology Co., Ltd. aim to achieve high-level VOC removal efficiency, ensuring that the treated exhaust gases meet or exceed specified emission standards.

Environmental Regulations: The company strictly complies with environmental regulations, ensuring that the exhaust gas treatment process meets relevant legal requirements, providing customers with compliant exhaust gas treatment solutions.

2. Reducing Air Pollution

Efficient Treatment: By efficiently treating organic exhaust gases, VOC concentrators can significantly reduce air pollution, protecting the environment and human health.

Environmentally Friendly: The company's exhaust gas treatment technology uses environmentally friendly materials and processes, reducing negative impacts on the environment and promoting sustainable development.

3. Promoting Sustainable Development

Resource Conservation: VOC concentrators promote the rational use of resources by efficiently treating exhaust gases and reducing resource waste.

Social Responsibility: Lv quan Environmental Protection Engineering Technology Co., Ltd. is committed to fulfilling its social responsibilities by using advanced exhaust gas treatment technologies to contribute to the sustainable development of society.

English

English русский

русский Français

Français Español

Español عربى

عربى