LQ-RTO Heat-storage high-temperature incineration equipment is an advanced organic waste gas treatment equipment, which plays a vital role in the field of industrial waste gas treatment. LQ-RTO Heat-storage high-temperature incineration equipment can effectively treat organic waste gas with its unique design principle and efficient working mechanism.

1. High temperature oxidation principle

The core working principle of LQ-RTO Heat-storage high-temperature incineration equipment is high temperature oxidation. After the organic waste gas enters the LQ-RTO Heat-storage high-temperature incineration equipment, it will be heated to a high temperature state (usually between 800℃ and 1000℃). In such a high temperature environment, organic compounds will react with oxygen to generate carbon dioxide and water vapor.

2. Application of thermal storage technology

The "heat storage" in LQ-RTO Heat-storage high-temperature incineration equipment means that it is equipped with a heat storage body, which is usually made of ceramic materials. These heat storage bodies have extremely high heat capacity and thermal conductivity. During the operation of the equipment, the organic waste gas passes through the heat storage body, which absorbs the heat in the waste gas and stores it. After the waste gas is heated to a high temperature and the oxidation reaction is completed, the purified gas passes through another set of heat storage bodies, which release the stored heat to preheat the incoming waste gas and reduce the energy consumption required for heating.

3. Multi-tower circulation design

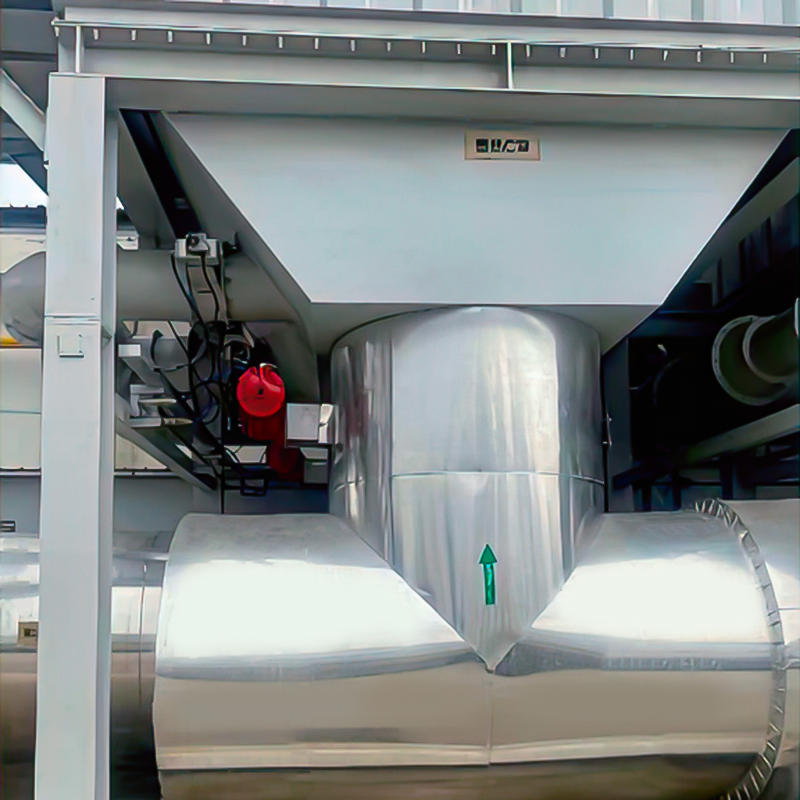

LQ-RTO Heat-storage high-temperature incineration equipment usually adopts a multi-tower circulation design,common of which are double-tower and three-tower types. The multi-tower circulation design enables the equipment to switch working states between different towers to achieve continuous operation. When one tower is in the heating oxidation stage, the other tower is in the heat storage preheating stage.

4. Energy-saving and environmental protection benefits

Because the LQ-RTO Heat-storage high-temperature incineration equipment adopts efficient heat storage technology and multi-tower circulation design, it can significantly reduce energy consumption in the process of treating organic waste gas. The LQ-RTO Heat-storage high-temperature incineration equipment can maximize the use of heat in the waste gas during operation and reduce operating costs. When treating organic waste gas, the LQ-RTO Heat-storage high-temperature incineration equipment can completely decompose harmful substances in the waste gas and reduce pollutant emissions.

5. Strong adaptability and wide application range

LQ-RTO Heat-storage high-temperature incineration equipment has strong adaptability and can treat various types of organic waste gas, including low concentration, high concentration, large air volume and other working conditions. It is widely used in chemical, pharmaceutical, printing, spraying, electronics and other industries, and has become an indispensable and important equipment in the field of organic waste gas treatment.

English

English русский

русский Français

Français Español

Español عربى

عربى