Lv quan Environmental Protection Engineering Technology Co., Ltd. is strategically located in the "Northern Gateway of Jiangsu"—Gaoyou City, Yangzhou Province. Our company is a joint-stock enterprise established by a team of professionals with over 30 years of experience in the design and manufacturing of VOCs equipment. With a registered capital of 22 million yuan, we have nearly 40 million yuan in fixed assets and a total asset value approaching 60 million yuan. Our production facilities span an area of 9,800 square meters, equipped with over 200 sets of various mechanical processing equipment. We employ a dedicated workforce of 120 staff members, and our annual production capacity is valued at 100 million yuan.

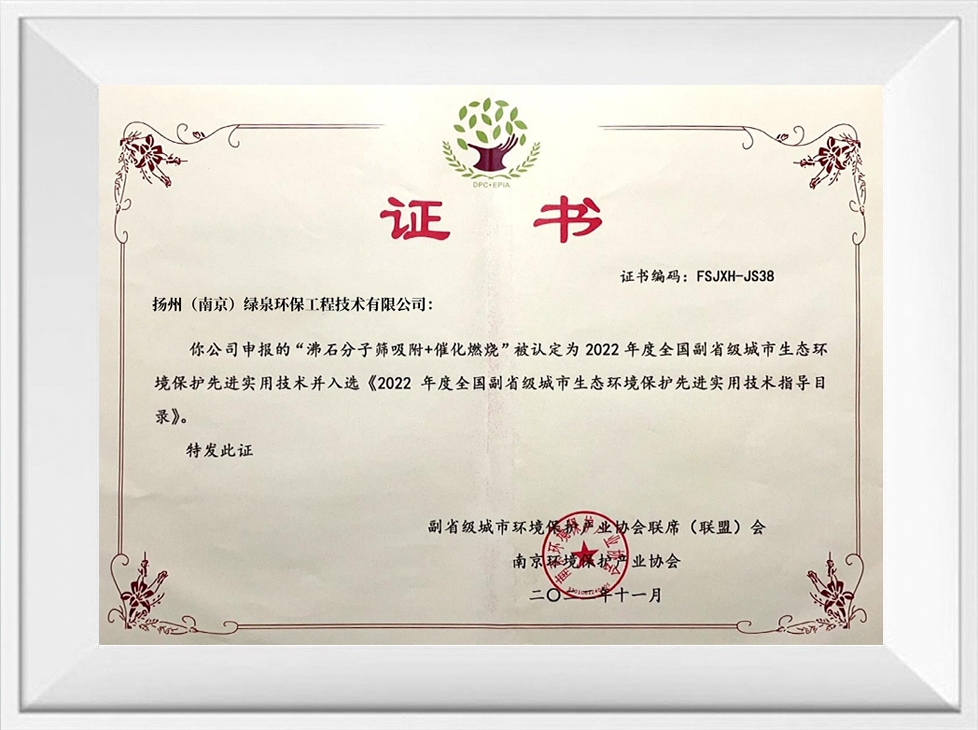

We are a professional organic waste gas treatment Equipment factory, The company has always focused on the environmental protection design and manufacturing of VOCs organic waste gas treatment such as "adsorption, incineration, recovery, pretreatment". It has been committed to the research, design, manufacturing, installation, and after-sales service of organic waste gas treatment equipment for more than a decade. The company has Jiangsu Province environmental pollution design and governance double-grade qualifications, Jiangsu high-tech enterprises, ecological protection professional third-level contracting qualifications, and has successfully passed the ISO9001, ISO14001 system certification.

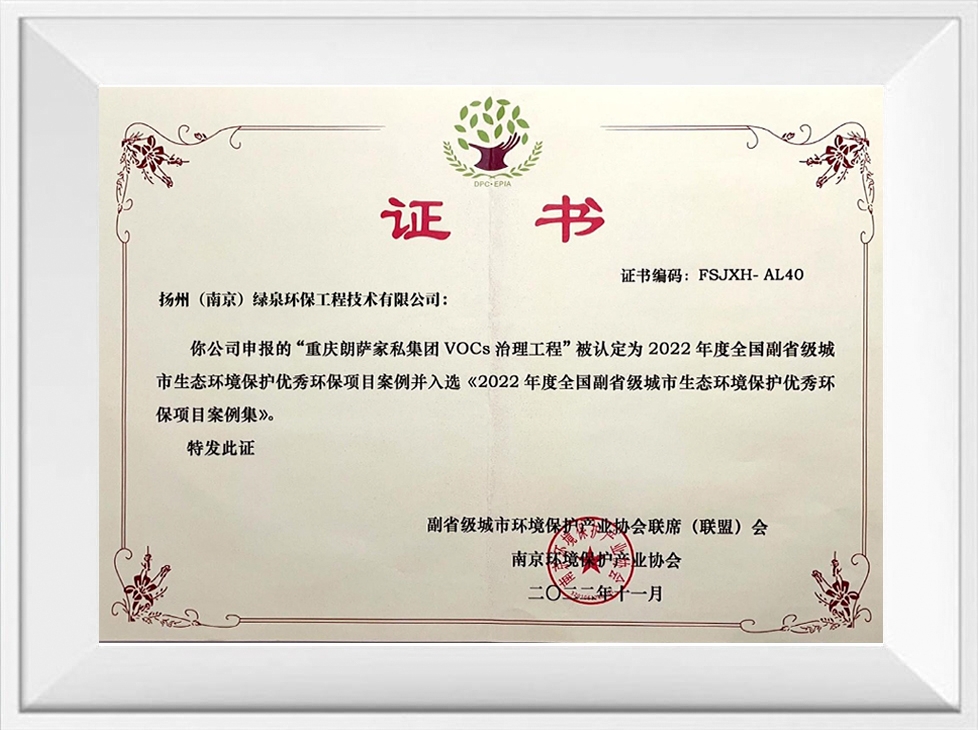

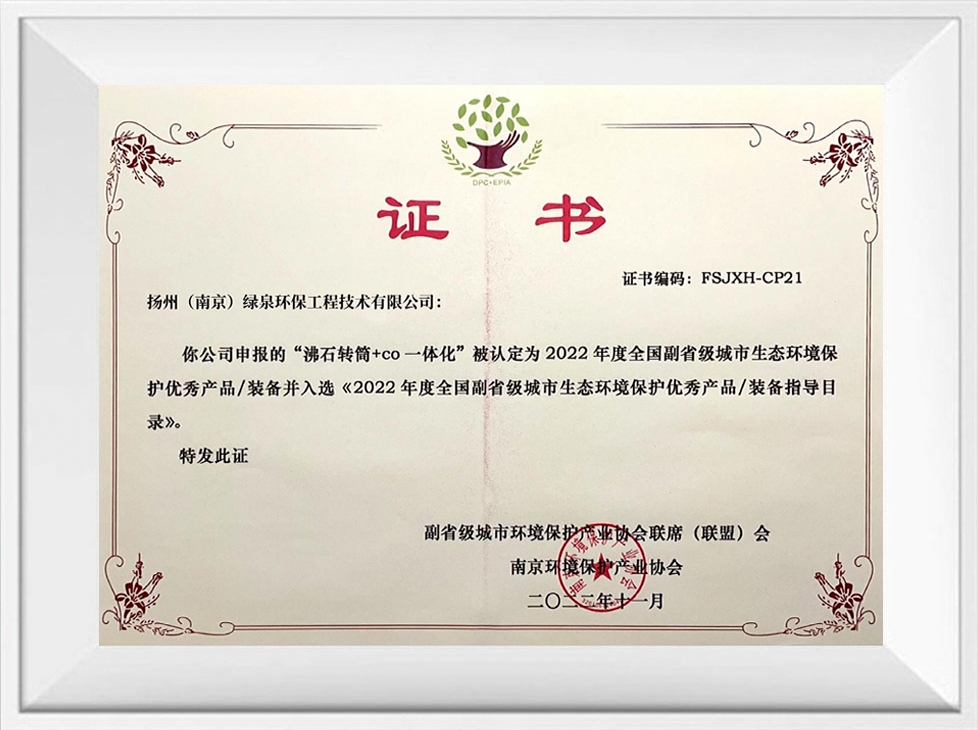

As a professional organic waste gas treatment equipment company, Our company currently holds thirteen utility certificates and two high-tech invention certificates, and we have been designated as a member unit of the Jiangsu Environmental Protection Industry Association. Our product portfolio spans a wide range of industries, including vehicle manufacturing, coil coating, petrochemicals, pharmaceuticals, electronics, machinery, printing, and furniture-building materials. In the field of organic waste gas treatment equipment, the Lv Quan brand stands out and enjoys a rapidly growing market share.

Adhering to the principles of "focus, technology, quality, service, and satisfaction," Lv Quan has absorbed and integrated advanced foreign technologies in the manufacturing of adsorption and incineration technologies. We have summarized and enhanced the safety, stability, and reliability of our products, achieving a level of quality that is on par with domestic peers and gradually replacing the need for imported equipment.

The Core Significance of Sealed Design VOCs Organic Waste Gas Treatment Engineering Equipment must employ a sealed structure; this is fundamental to e......

READ MORE

English

English русский

русский Français

Français Español

Español عربى

عربى